Compounding, Extrusion,

Lamination, and More

We provide everything from outsourced R&D to simple toll conversion.

Our Capabilities

Specialty Materials and R&D

x Materials: HDPE, TPO, PP, ABS, StyrenicsCoextrusions: A-B-C coextrusions

Gauges: 0.020” to 0.250”

Laminations: Single-sided films, scrims, foams, carpets, non-wovens and lofted fibers – corona treatment

Complex Laminations

x Materials: Heavy Layer CompoundsCoextrusion: ABC Layers

Gauges: 0.020” to 0.250”

Laminations: Double sided – films - foils – scrims – carpets – non-wovens and lofted fibers

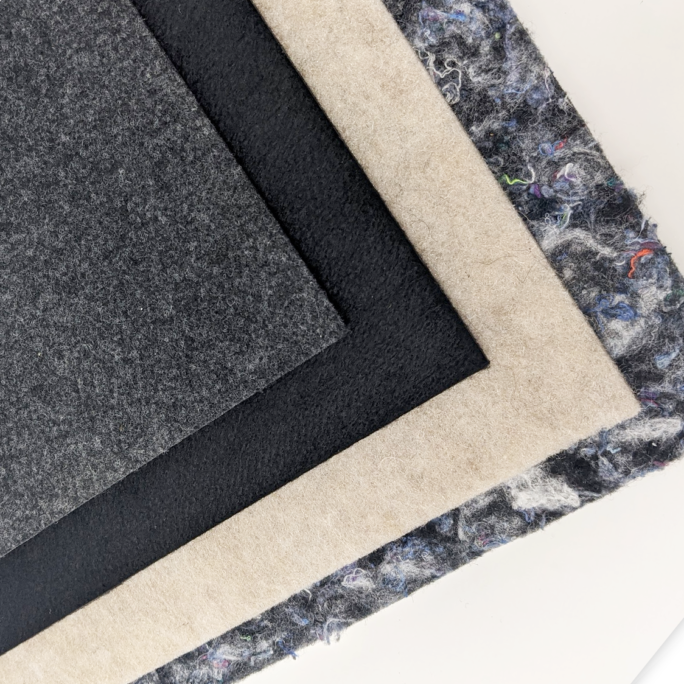

Deep-Draw NVH Materials

x Materials: Filled Thermoplastics, HDPE and PEGauges: 0.020” to 0.390”

Laminations: Double sided films, scrims, foams, carpets, non-wovens and lofted fibers

Closed Loop Recycling

x Materials: Specialized for closed loop recyclingCoextrusion: AB

Gauges: 0.020” to 0.390”

Laminations: Double sided – films – scrims – carpets – non-wovens and lofted fibers

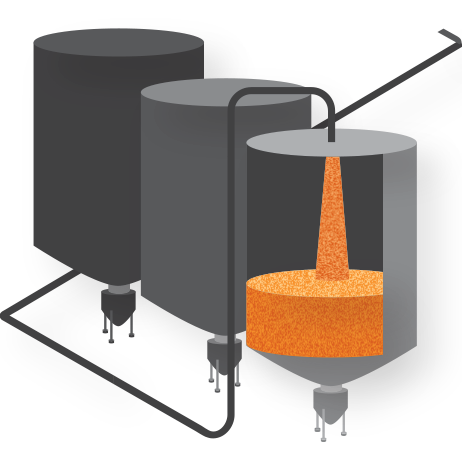

Compounding

x Feeders: Powder, Pellet, Oil, Micro feedersExtruder: Includes underwater pelletizer and additional dryer

Materials: Filled Materials

Residence Time: 2 minutes

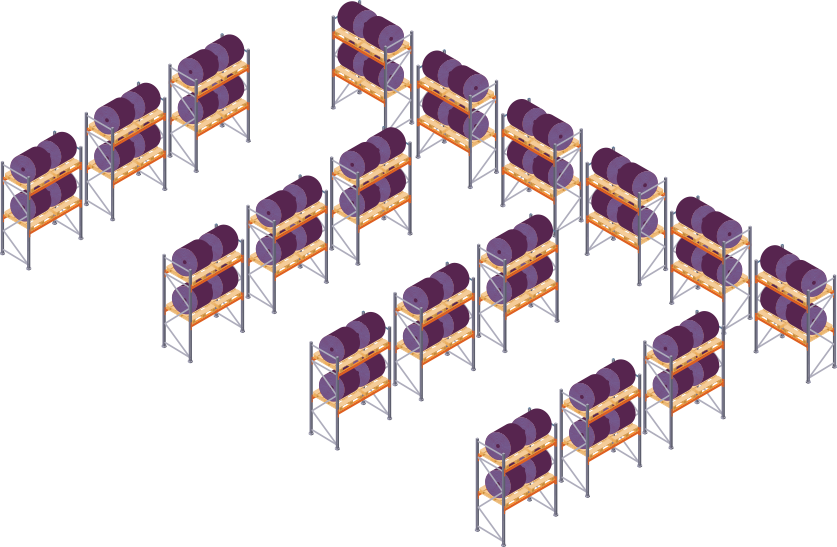

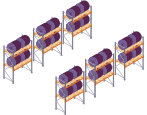

Warehouse and Logistics

x Supports inventory and stocking agreements

Large Warehouse

Supports inventory and stocking agreements

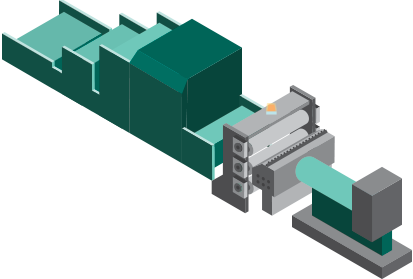

Compounding Line

Feeders: Powder, Pellet, Oil, Micro feeders

Extruder: Includes underwater pelletizer and additional dryer

Materials: Filled Materials

Residence Time: 2 minutes

Automotive NVH Closed Loop Recycling

Materials: Specialized for closed loop recycling

Coextrusion: AB

Gauges: 0.020” to 0.390”

Laminations: Double sided – films – scrims – carpets – non-wovens and lofted fibers

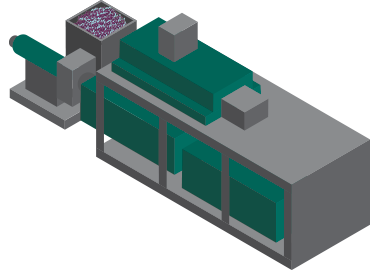

Automotive NVH Materials

Materials: Filled Thermoplastics, HDPE and PE

Gauges: 0.020” to 0.390”

Laminations: Double sided films, scrims, foams, carpets, non-wovens and lofted fibers

Automotive and Specialist Laminations

Materials: Heavy Layer Compounds

Coextrusion: ABC Layers

Gauges: 0.020” to 0.250”

Laminations: Double sided – films – foils – scrims – carpets – non-wovens and lofted fibers

Non-Automotive and R&D

Materials: HDPE, TPO, PP, ABS, Styrenics

Coextrusions: A-B-C coextrusions

Gauges: 0.020” to 0.250”

Laminations: Single-sided films, scrims, foams, carpets, non-wovens and lofted fibers – corona treatment

Flexible Services Tailored to Your Requirements

We can offer complete program solutions, from custom R&D through to recycling of post-processing waste material, including outsourcing secondary manufacturing processes. Our dedication to customer service underpins our entire operation.

- Extrusion

- Compounding

- Lamination

- Scrap buy-back

- Surface treatment

- Custom R&D

- Resin Casting

- Multilayer Extrusion